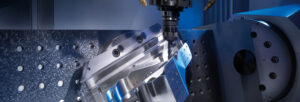

In the discourse confine as shown Figure 10.9, Set Target Cell is the place where one demonstrates the target capacity to be advanced (boosted, limited, or focused to a specific worth). The choice Equal To gives one the choice of treating the objective cell in three elective manners. Max advises Solver to amplify the objective cell and Min, to limit it, while Value is utilized in the event that one needs to arrive at a specific estimation of the objective cell by picking a specific estimation of the endogenous variable. On the off chance that one picks Value, one should enter the specific worth one needs to accomplish in the container to the quick right except if one needs the worth to be zero (default). This cell should contain an equation that relies upon at least one of the other cells. All in all, it ought to incorporate at any rate one changing cell Changing cells are the spreadsheet cells that we can change or conform to upgrade the objective cell By Changing Cells licenses one to demonstrate which cells are the evolving cells (ie., plan factors). Each non contiguous decision variable is isolated by a comma. On the off chance that one uses the mouse technique (tapping on the cell), the comma division is programmed. Theory controls the underlying position of the evolving cell. Dominate utilizes the current estimations of the cells as the default. Solver is delicate to the initial values. On the off chance that an answer can’t be discovered, attempt diverse gazing values. Since Excel is sensitive to gazing values, many ought to be attempted to recognize a neighborhood and worldwide ideal. Precision cnc prototype manufacturers utilizing numerous new beginning qualities will look through a greater amount of the arrangement space. Without a doubt, a worldwide ideal undoubtedly won’t ever be found if the capacity is intricate.’ However, utilizing multiple focuses will give a superior arrangement in light of the fact that the sum up diminished slope strategy is in the hill climbing classes of algorithms, which implies it will stop when the angle will zero or approach zero.

Subordinates, or slopes, assume a vital part in iterative strategies in Solver. They give signs with regards to how the changing cells ought to be differed. For instance, if the objective cell is being amplified and is fractional subsidiary concerning one changing cell is an enormous positive number, while another halfway subordinate is close to nothing, Solver will likely expand the main changing cells esteem on the following cycle. A negative halfway subsidiary proposes that the connected changing cells worth ought to be fluctuated in the contrary direction. Since the first subordinate of the objective cell estimates its pace of progress concerning the evolving cells, when the entirety of the partial subsidiaries of the objective cell are zero, the main request conditions for optimal have been satisfied, the most elevated (or lowed) conceivable value for the objective cell having been found.

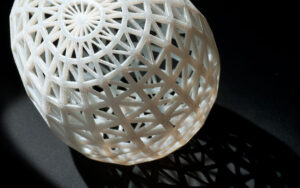

A few issues have numerous locally ideal focuses, where the incomplete subordinates of the ideal cell are zero. A chart of the ideal cell work in such cases would show numerous hills and valleys of shifting statures and profundities as demonstrated in china rapid prototyping suppliers. When begun at a given arrangement of changing cell esteems, the strategies utilized by Solver will in general merge on a solitary ridge or valley floor near the beginning stage. Be that as it may, Solver has no definite method of knowing whether a worldwide ideal has been reached. One approach to track down the worldwide ideal is to apply external information to the issue, either through sound judgment thinking about the issue or through experimentation. Alternatively, one can utilize Monte Carlo advancement strategies to come more like a worldwide ideal utilizing dominate.

Imperatives are restriction to put on the changing cells In the organization’s model presentation model, some plan attributes have certain limitations. For instance, the greatest components of the item are restricted by the genuine utilization of the item, and the base size of the item is restricted by the size of the engines inside. Prototype manufacturers china records the limitations for the issues introduced in oem rapid aluminum prototype factory.

This article is from https://www.precisiontype.com/